TAG CMMS maintenance software

Simple to use and easy to scale, TAG CMMS maintenance software automates annoying administrative tasks so that your teams can focus on the work they truly enjoy.

What is a computerized maintenance management system (CMMS)?

A computerized maintenance management system (CMMS), also known as CMMS maintenance software, is designed to simplify the maintenance of all your assets. A CMMS enables organizations of all types to eliminate manual data entry and easily track the performance and state of health of all equipment in one centralized, digital location. The main functions of a CMMS include maintenance scheduling, managing spare parts inventory and work orders, and tracking asset data and business resources like labor, contractors and materials.

TAG CMMS is a highly scalable maintenance and asset management software. Looking to upgrade from an old CMMS? Want to move away from paper-based processes or ditch mind-numbing manual spreadsheets? TAG is an easy-to-use solution that lets you start small with a simplified maintenance management process that requires corrective and reactive actions. You can then transition to a hybrid setup with a CMMS for managers and paper-based workflow for maintenance staff. Then, take the next step to a more sophisticated automated maintenance program based on preventative and predictive analyses.

What can companies and maintenance teams achieve with TAG CMMS?

Progressively transition to CMMS and EAM

TAG is a plug-and-play CMMS that has minimal initial implementation costs and reduces all the hassles associated with workers’ resistance to adopting new technology. Start small with simple CMMS features and activate more advanced EAM features when you are ready.

Never miss a maintenance procedure

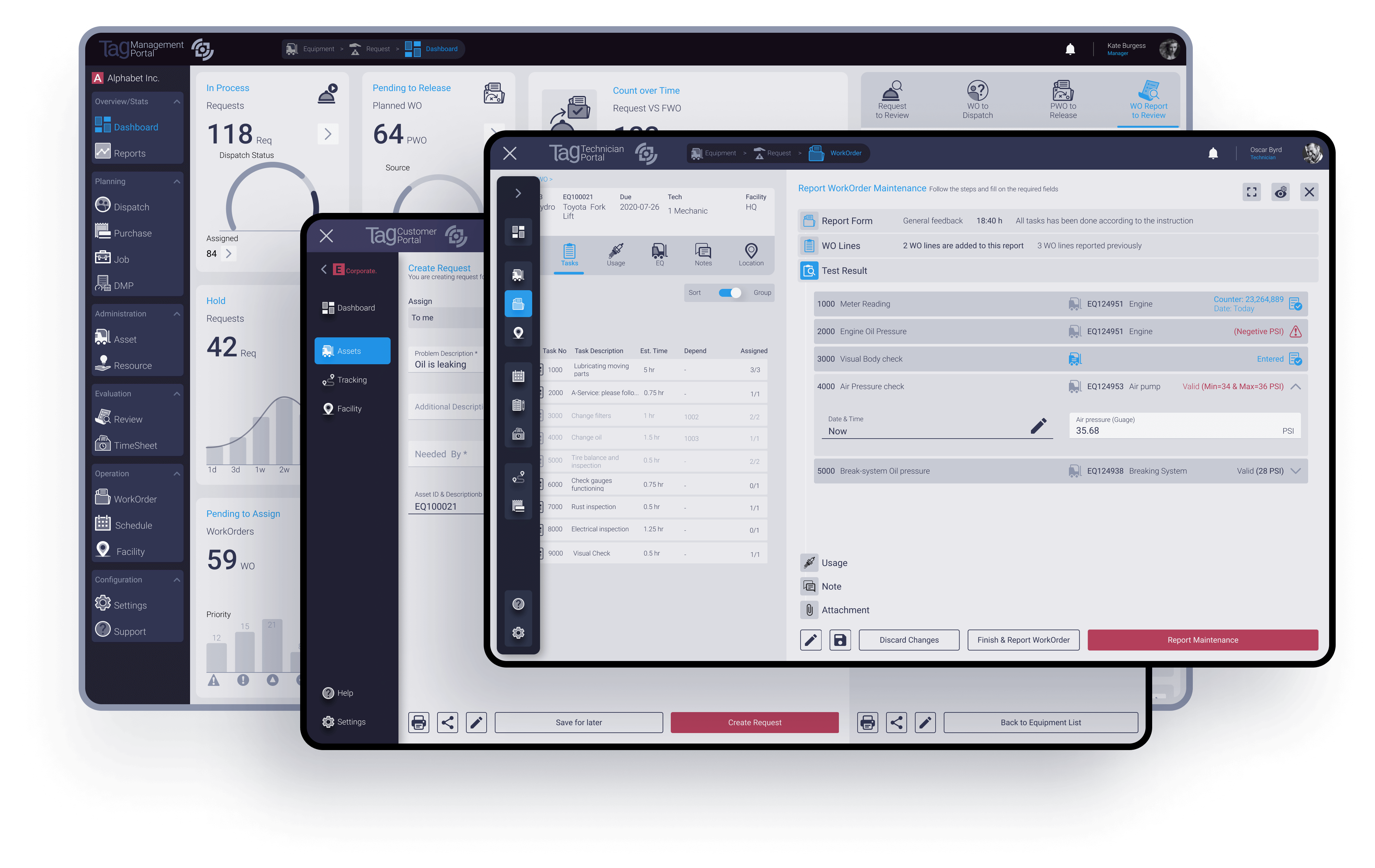

TAG’s powerful maintenance workflow automation will ensure you never miss a maintenance procedure. Our solution will guide you step-by-step to carry out your equipment maintenance on time, accurately and safely.

Boost your productivity and keep costly downtimes at bay

With TAG, you can effortless monitor your equipment’s state of health and plan for effective preventative maintenance procedures. It is the best CMMS on the market to avoid equipment failure and disruptions to your production lines.

Improve your team’s workflows

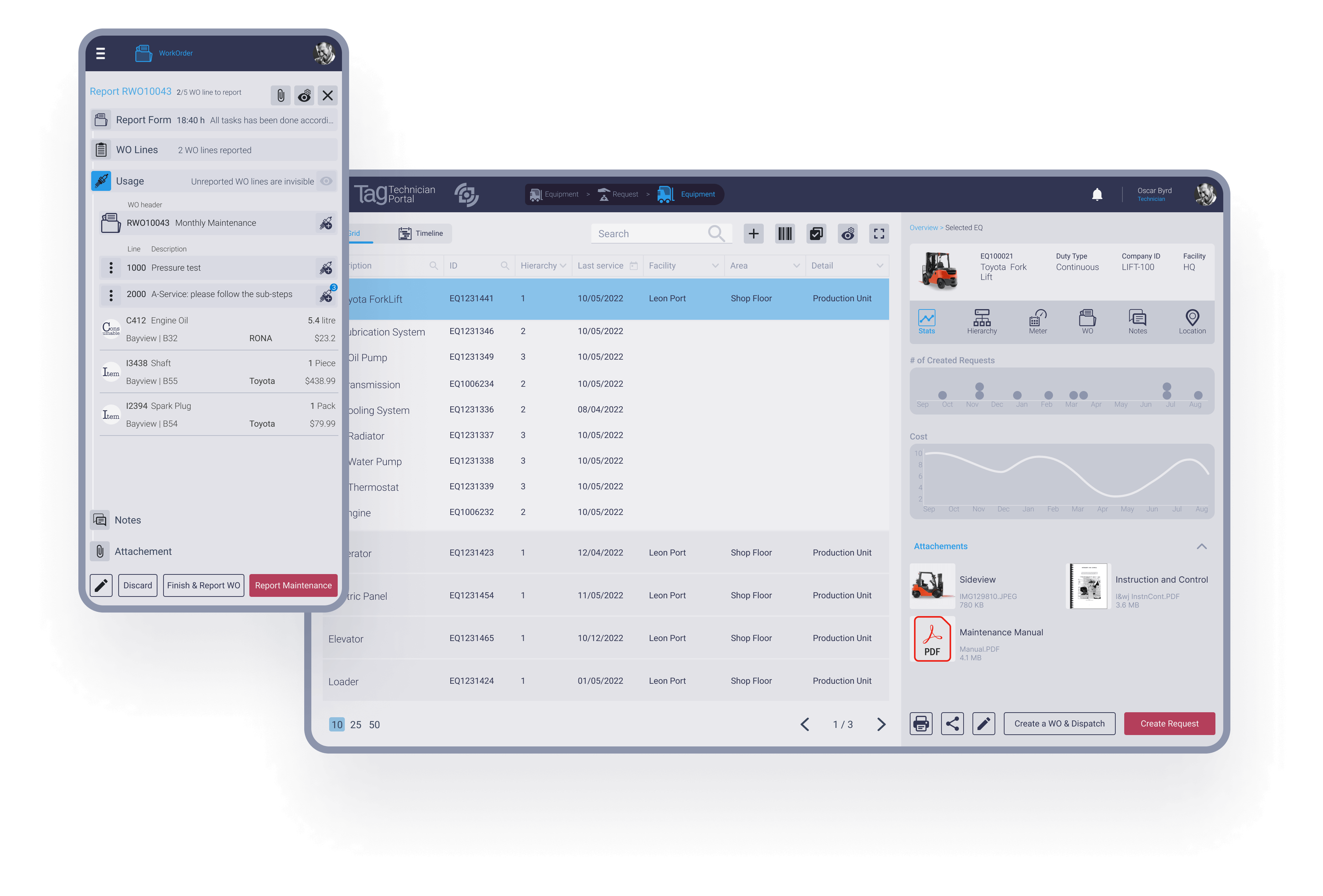

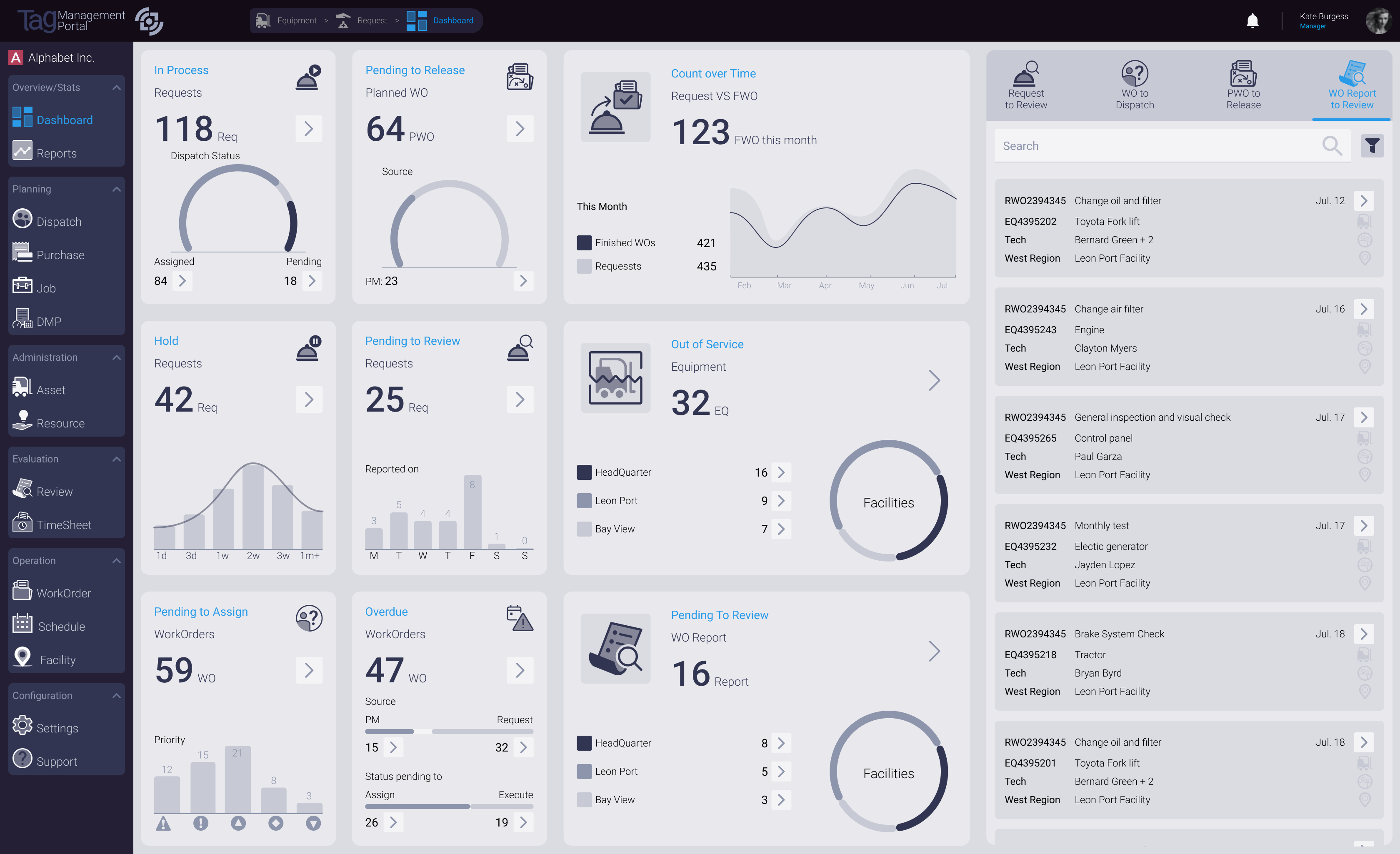

Operators and production staff can track, in real time, all the maintenance requests they submit. Technicians also have access to all related information to the tasks to execute as well as documentation and history on the equipment. Managers can track all requests and work order statuses, equipment and assigned technicians.

Better manage your inventory

Get complete, accurate visibility on your inventory for anyone in your team, from purchasing to technicians out in the field. TAG CMMS helps your team to minimize overstock and maximize stock availability by location.

Keep track of your assets

Use TAG CMMS’ location capabilities to never lose track of your equipment—whether it is in production, in a facility, in the field, in storage, in repair, or in service at a vendor site. With TAG’s map views and CAD drawings of all your equipment, you will have better control of your complete asset park.

Access staff statistics for better decision making

TAG CMMS lets you optimize your workforce to be more efficient by tracking statistics on maintenance teams and operators, such as equipment usage, availability, etc. Technicians can even log data in real time so that you are always in the know of where they are landed in a maintenance process.

Get historical data on equipment costs and state-of-health statistics

With one click in TAG CMMS, you can extract any statistic you need on your equipment, including full history and details on repairs and maintenance failures. Thanks to accurate KPIs and easy-to-understand ROI reports, you can make better decisions to optimize your investments.

TAG CMMS’s key features

Equipment cards and sub-assemblies

Centralize all related equipment and sub-assembly information in one place, with details at the individual or roll-up-to-top level. TAG CMMS gives you one version of the truth of all your asset-related activities, costs, budgets and statistics.Work request and order handling

Once a maintenance request or work order is initiated, execute corrective maintenance using pre-established workflows. Technicians can print a work order or access it electronically to punch their time, and pick parts and materials from on-hand inventory to complete their jobs.

Vendor and contractor management

TAG CMMS lets you assign and track work orders and purchase orders with vendors and contractors. Managers can oversee all requests in real time—from initial entry and approval through purchase orders, receipts and invoicing.Inventory of consumables and parts

Date-based preventive maintenance

Initiate preventive maintenance work by date to automate maintenance work order creation and never miss a regular maintenance procedure. Activate TAG EAM’s advanced features to scale to true meter-based preventive maintenance.Work procedures

Create work procedures by type of maintenance or failure codes to prepopulate your work orders. Each work order can include mission-critical information, such as task type, required skills, tools needed, estimated time to completion, specific technician to be assigned to the job, etc.

QR code and barcodes

Dispatch and calendar views

Use TAG CMMS’s drag-and-drop functionality to dispatch tasks to available technicians. Properly assign tasks with alerts if technicians have the wrong skills or certification match. Technicians can access their workloads in the calendar view and drag-and-drop their tasks to better organize their days.Looking to improve the way you manage your maintenance? Our team will be happy to show you how TAG CMMS can help you!

Featured Content

Use Case

Industries

Platform & Technology

What is Computerized Maintenance Management System (CMMS)?

What comes into your mind when you hear the term Computerized Maintenance Management System? Also identified by its...

http://What%20is%20Computerized%20Maintenance%20Management%20System%20(CMMS)? Read More »

Computerized maintenance management software (CMMS) is the heart of intelligent work orders. Three smart strategies for increasing maintenance...